Round Manhole Repairs vs. Square Manhole Repairs

After a road resurfacing, manhole frames and lids need raised to the new road height. This is accomplished by removing a section of the road around the manhole lid and rebuilding the structure at the appropriate level. In the past, workers have cut a square area out and replaced it during the rebuilding process.

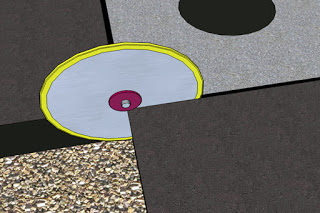

The past decade has seen advances in cutting technology allowing full penetration round cuts through concrete and asphalt roads. There are many benefits to a round cut as opposed to a square cut. A round cutter can achieve a perfect circular cut fully penetrating the road. If you use a concrete saw to penetrate the road you are cutting a square with a substantial over cut at each corner. This over cut is an ongoing maintenance issue. Read More

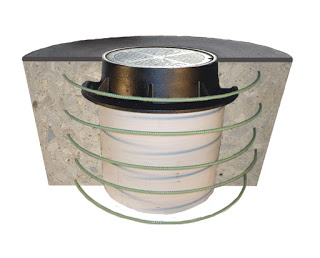

It is difficult to properly reinforce a square cut and indeed many are without any reinforcing. With a round repair, circular re-bar rings allow optimum reinforcing.

A round repair requires twenty percent less excavation and twenty percent less material to replace. This is a huge savings in labor and material. If the cost to excavate and replace is $10,000 for your project; using a round repair could save as much as $2,000. Read More

A round collar makes the gradient transition from the frame to the road easier and more aesthetic as it is an equal distance around the lid unlike a square repair with its jutting corners.

By eliminating the corners we minimize the destructive forces caused by the moment arm generated at the corners. When a square collar is placed around a round manhole frame the planes of weakness created by the varying collar width causes cracking and premature failure.

A round collar has a smaller perimeter to maintain reducing ongoing maintenance costs. This smaller perimeter reduces the possible entry points for water to penetrate the pavement and leak into the manhole structure.

In cold weather states the round structures are more resistant to frost heave. The round structure is less obtrusive to snow plows. It presents substantially less frontal area to impede the plow.

The round manhole repair is aesthetically more pleasing than a square repair. It is using the appropriate tool for the job and shows pride and professionalism.

Round manhole repairs are fast becoming the norm around the world. The costs of worker injuries are driving engineers to find safer methods of removal and replacement for manhole frames. Manholes are not going away and they must be maintained so traffic can continue to flow. It behooves us to adopt the safest and most economical repair methods. Repairs must be made periodically and they should be safe and of high quality. Round repairs will always be superior to square in every way.

Mr. Manhole is a fully engineered solution for manhole chimney repair. Solve the bump and leak while saving money.

Square Manhole Repair

Square Manhole Repair

Illustration of Concrete Saw Over-cuts on each corner

Illustration of Concrete Saw Over-cuts on each corner

Cutaway of a Round Repair with circular re-bar

Cutaway of a Round Repair with circular re-bar

Uneven gradient transition from road to concrete manhole collar

Uneven gradient transition from road to concrete manhole collar

Cracking due to planes of weakness at each corner

Cracking due to planes of weakness at each corner

Round Manhole Collar

Round Manhole Collar

Related Articles

The XL Speedplate

When your customer’s in the field, we don't know what manholes they're going to encounter. Sometimes they might encounter a very large manhole frame, like for Verizon or an electrical manhole, a

Rentals & What to Ask Customers

If you're talking to a customer about a rental unit and you're asking them what they're going to need, you need to make sure and ask them if they've looked at the manhole frames. Have they taken the l

Accounting for different manhole types

As a salesperson for Mr. Manhole you may have a customer that says, I just want the standard speed plate. I don't want anything else. And that's fine. But when your customer has the road shut down, he

Smoothwall Rollpin

You'll notice these roll pins that are in the ends of each side of the speed plate, and their function is to keep the speed plate together. So you always want to make sure they're there and in good sh

Comments