Hawaii Case Study

The beautiful Hawaiian islands are a favorite vacation spot for people from all over the world. Visitors use the roads in Hawaii for transport to their favorite attractions. What they may not notice is the behind the scenes work to keep the roads maintained. Major road construction companies like Grace Pacific maintain those roads. The roads in Hawaii have an unusual amount of manholes and water valve structures which present a problem for pavers. Most paving projects in the islands require milling the road before paving. The milling and paving are much easier if the manholes and water valve structures are removed and steel plated. This process allows the milling and paving machine to operate as if the structures are not there. Not having to work around these structures makes for a much smoother roadway.

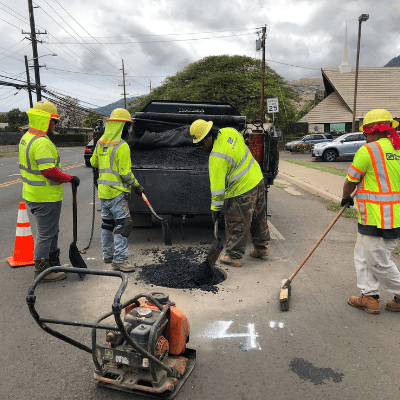

Grace Pacific representatives visited the Ohio offices of Mr. Manhole to research options to perform this work in a more efficient manner. They saw the Mr. Manhole cutters and the proprietary New Construction method for installing and removing steel plates. Grace Pacific purchased the Mr. Manhole system for testing on the islands and subsequently made a second purchase. The company currently has two crews performing lowering and raising operations in conjunction with the paving crews. The crews have to maintain traffic during all operations so speed is very important. They have developed an efficient system to perform these operations. A typical lowering consists of cutting and pulling the manhole or water valve frame and placing a steel plate. The structure is GPS located, and after milling and paving is located and marked. The crews use the same Mr. Manhole cutting equipment to cut and restore the structure. (See Newcon method) The crews average about 25 minutes per structure to lower and about 30 minutes raise a structure. Mr. Manhole technicians have worked with Grace Pacific crews to tailor tools and methods that function well with local job conditions. Grace Pacific has completed 1200 repairs to date with many more to come.

Mr. Manhole Hawaii Case Study

Want to find out more about the Mr. Manhole tool revolutionizing the way manholes are repaired?

With traditional methods, manhole removal and repair is a tedious, laborious job that requires heavy lifting and risk of injury to the worker

The Mr. Manhole method allows you to repair manholes faster, smarter and safer.

Related Articles

The XL Speedplate

When your customer’s in the field, we don't know what manholes they're going to encounter. Sometimes they might encounter a very large manhole frame, like for Verizon or an electrical manhole, a

Rentals & What to Ask Customers

If you're talking to a customer about a rental unit and you're asking them what they're going to need, you need to make sure and ask them if they've looked at the manhole frames. Have they taken the l

Accounting for different manhole types

As a salesperson for Mr. Manhole you may have a customer that says, I just want the standard speed plate. I don't want anything else. And that's fine. But when your customer has the road shut down, he

Smoothwall Rollpin

You'll notice these roll pins that are in the ends of each side of the speed plate, and their function is to keep the speed plate together. So you always want to make sure they're there and in good sh

Comments